-40%

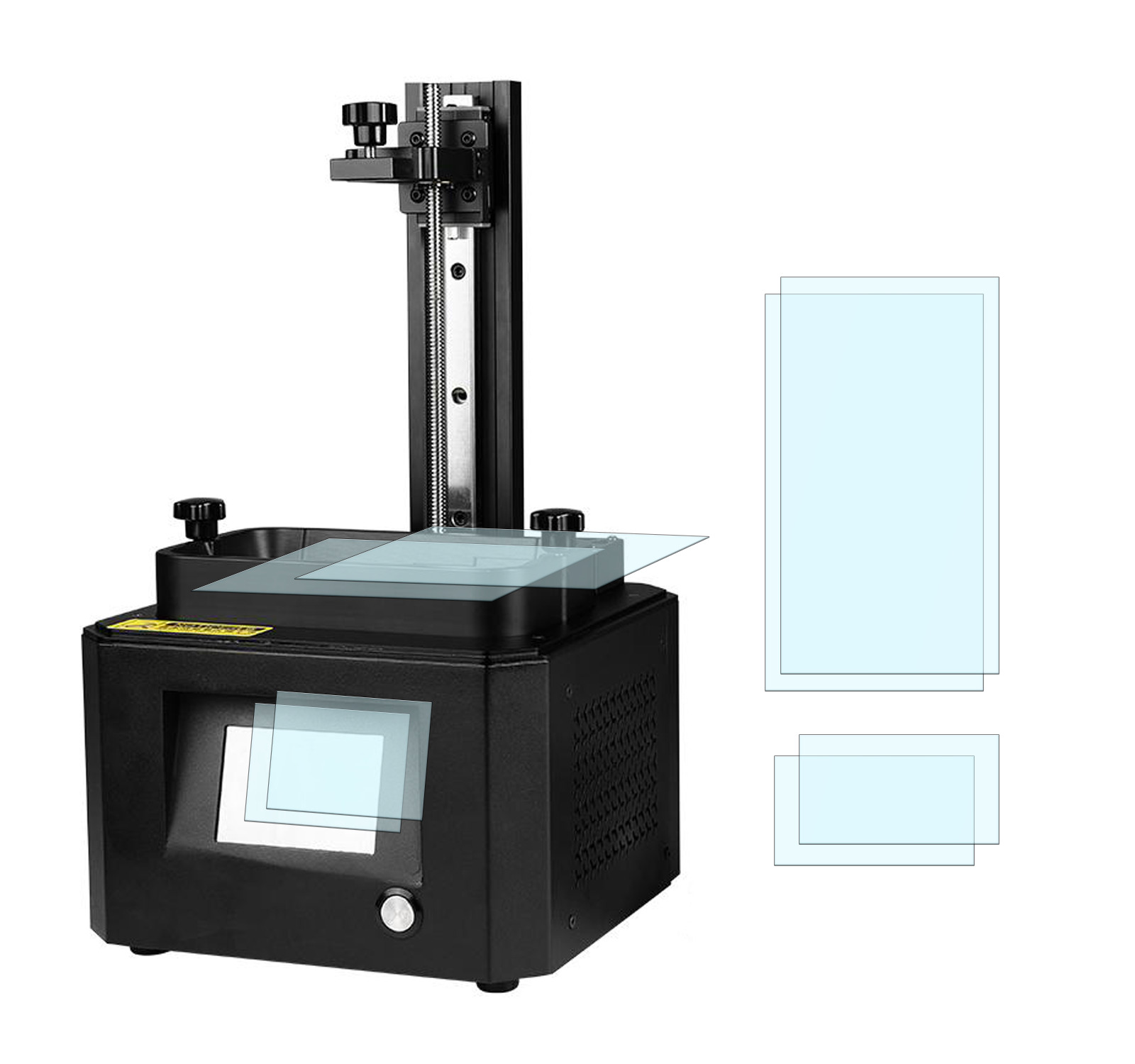

2PCS Sovol Resin Flexible Plate135x80cm Anycubic Photon Mono / Mono SE/Mono 4k

$ 5.8

- Description

- Size Guide

Description

(135x80mm )For Anycubic Photon /Photon Ultra /Photon S /Photon Mono / Mono SE /Photon Mono 4kProduct Description

Flexible Plate Features

1. Stainless spring steel with high chromium content, easy to bend and clean, good corrossion resistance and prevent rust.

2. Hairline finish on surface makes the adhesive better, ensure the print successful. The other side is smooth without processing. Both sides etched for great part adhesion.

3. 2 easy lift tabs(handles) make it easier to remove the steel plate from the magnetic base.

4. Continuous printing with 2 Plates, start another print before you start cleaning the first!

Magnetic Base Features

1. Powerful magnet with alternating polarity to resist FEP suction.

2. Custom 3M adhesive impervious to resins and solvents. The 3M adhesive has strong viscosity and good adhesive at low temperature to make it hard to fall off after bonding with metal.

Materials Download

1.Contact with Seller to share the link

2.Click to download the STL file of a spacer to re-level your bed.

Package Content

2*Flexible Build Plats + 2*Magnetic Bases

Video about item

Ensure your build plate is thoroughly cleaned.

Remove any liquid resin using an appropriate solvent (e.g isopropyl alcohol). Ensure there is no oil, water, detergent, dust or any other foreign matter on your build plate and that it is fully dry. It’s worth running it under a UV light (or the sun) to be extra sure that there is no liquid resin remaining. Any foreign matter will negatively affect the adhesive.

Check it’s the right temperature and humidity.

Before you start, make sure the temperature of your environment is between 21°C-38°C (67°F-100°F) and the humidity is between 40%-60%. If the temperature is too low you can heat the build plate up a bit for this process. This temperature range only applies for the install process. Once the magnet is attached, and the adhesive set, it will work fine outside these temperatures.

Install the magnetic sheet.

Before removing the tape protecting the adhesive, line up the magnetic sheet with the build plate to check the positioning. Peel away about 1-2cm of one end of the protective tape and begin attaching the magnetic sheet to the build plate. Press it down from the middle to the corners, being careful to ensure you don’t capture any bubbles. Slowly peel back a bit more of the tape and repeat this action, until you have completed the whole sheet. Burnish the surface by placing the protective tape on the magnetic surface and massaging it very firmly with your finger-tips (through the tape), covering every spot of the magnetic surface.

Allow the adhesive to set

The adhesive will be fully set in 72 hours, but if you’re in a hurry it will set to about 90% efficacy in 24 hours.

Place the stainless-steel plate onto the build plate.

With the smooth side toward the magnet, which will hold it in place. Ensure the tabs won’t hit the tank in the placement you choose.

Re-level your build-plate

To account for the increased thickness of the build plate, you will need to re-level your build-plate according to the normal procedure for your machine. Be sure to loosen all the screws before homing the printer slowly in increments, as you have added bulk to the build-plate during this installation, and you don’t want to accidentally crack your screen.

Note: some machines don’t have much play in their homing function, and in such cases you may need to move your Z end stop slightly (that’s the little switch that tells your printer where ‘home’ is) to account for the thickness of the flexible plate (roughly 2.7mm). Some machines may need a spacer to achieve this placement. A printable STL of which can be found

. Basically, this tricks the printer into thinking home is a little bit higher than it used to be. This will also reduce your maximum print height by 2.7mm.

Print!

Slice your print as normal and print it out. If your prints aren’t sticking to the stainless-steel plate, ensure you are printing on the brushed side, with the smooth side facing the magnet. The brushed steel side adheres better to the resin. If you are still having trouble, increase your initial layer time in your slicer software.

Pop your prints off

When your print is complete, remove the stainless-steel plate from the machine using the little tabs, and flex it lightly to pop your prints off. You shouldn’t need to bend the plate drastically to remove prints, and doing so could irreversibly damage the plate. If you find your prints are hard to remove, consider lowering your initial layer time.

Clean the plate and magnet and reattach it

Ensure there isn’t any residue caught between the stainless-steel plate and the magnet and that the plate is dry before re-assembling. If you have two stainless-steel plates you can quickly clean the magnet then snap on the clean stainless-steel plate while you finish cleaning the freshly-printed one, to speed up your production line.